Canada’s weekly soybean crush is running at a very strong pace, as favorable margins for processing the crop, and tight supplies of canola, cause those plants with flexible capacity in Eastern Canada to increase the percentage of soybeans moving through their facilities.

That represents the highest weekly level of the past five years that reports are available, and comes in well above the average weekly soybean crush of about 27,000 tonnes. Canada has crushed 503,336 tonnes of soybeans during the 2012-13 crop year to date, which compares with 435,090 at the same point the previous year.

It’s a protein-driven market right now," said a processing company official, accounting for the increased interest in crushing soybeans, which have a higher meal content than canola. However, he was reluctant to read too much into the weekly numbers and would not comment on how long the increase in the soybean crush might last.

Canada’s soybean crushing capacity is primarily situated in Ontario and Quebec, where the bulk of the crop is grown in the country. Processors there are flexible and can also process canola, which is mostly grown in the West.

Tight supplies of canola in Western Canada and unattractive crush margins for the commodity likely caused some processors in Eastern Canada to switch over to soybeans, said oilseed analyst Chris Beckman of Agriculture and Agri-Food Canada’s market analysis division in Winnipeg. Beckman forecasts the country’s total soybean crush in 2012-13 at 1.4 million tonnes, but said that number would likely end up larger as the switch to processing more soybeans should continue through the crop year.

Right now, crushing soybeans is quite a bit more attractive than crushing canola," he said. Using his calculations, soy crush margins were averaging around $100 per tonne, while the canola crush margin was only about $10-$20 per tonne. Processors were seeing profits for crushing canola in the $100 range at this time last year.

Nature always wins. Want proof? Consider the corn rootworm. “This bug eventually has found a way to resist nearly every control technique we throw at it,” says Bruce Hibbard, a USDA-ARS research entomologist based at the University of Missouri.

This pest doesn't give up easily. The latest weapon, Bt technology, promises to deliver a knockout punch bred inside the plant itself. It's showing vulnerability, however. Corn in some Corn Belt fields is succumbing to yield-robbing root damage, even when a Bt hybrid is planted. Bt will play a strong role in rootworm control for years to come, says Hibbard. Still, if we want to maximize its long-haul effectiveness, we may need to revert to previous technology in multiple-mode warfare. Here's his checklist of rootworm control technologies – some from the past – that can help you reduce the overall levels of infestation.

For the first 50-plus years of the last century, this was the only rootworm defense. “It breaks the cycle of the pest,” Hibbard explains. Rootworm pupates into the adult stage late in the growing season. Females then lay eggs that overwinter and hatch again the next spring. Corn-on-corn really plays into their game plan. If no corn roots exist in the field due to planting soybeans or another crop, the larvae starve and the population is greatly reduced. In many places, rootworms have found a way to get around crop rotation – but not completely. Usually, rotation helps to reduce root feeding. If it is possible to rotate crops, you may have to do that to help maintain high corn yields, Hibbard says.

This second-generation control technology started back in the 1940s and 1950s. Initially, farmers broadcast chlorinated insecticides as a seed treatment. Resistance developed relatively quickly. Organophosphates and carbamates were then developed, but they didn't offer an easy system to manage. They also were relatively expensive, so farmers banded them in the row furrow with the planter. This technology and the chemicals are as effective as ever, says Hibbard. Rootworm has shown little or no resistance to the carbamate class of chemicals in 40 years of use. Banding provides a natural refuge where rootworm can survive between rows outside the insecticidal bands. “The fact that resistance has not developed to this management tactic documents that refuges work for delaying resistance,” he says. “There are places where you can use it to your advantage now.”

This tactic is similar to rotating weed chemicals to prevent resistance development. With Bt corn, there are now second- and soon-to-be third-generation Bt modes of action that work in different ways than the original Bt. Thus, a rootworm that resists one Bt mode is susceptible to another. If you are rotating crops and soil insecticides where possible, Hibbard advises also rotating the type of Bt corn that comes in your seed package. The goal is to keep rootworm one step behind you in its fight for survival.

If rootworm resists a Bt mode of action, don't plant seed with solely that Bt mode, Hibbard says. If crop rotation or granular soil insecticides are not possible, plant Bt corn hybrids that stack the modes of action with more than one source. That improves the effectiveness, and fewer rootworms should survive to reproduce.

Nanoscale pollutants can enter crop roots, triggering a host of changes to plants’ growth and health, two studies find. These tiny particles can stunt plant growth, boost the plants’ absorption of pollutants, and increase the need for crop fertilizers. Nanomaterials that get released in the exhaust from diesel-fueled tractors can rain down onto crop fields. Those used in fabrics, sunscreens and other products collect in the solids separated out of sewage and wastewater — nutrient-rich solids that are routinely spread on U.S. fields to improve soils. The new studies offer a glimpse at the toxic effects such nanoparticles may pose to future crops as exposures rise. The new data now “forewarn of agriculturally associated human and environmental risks from the accelerating use of manufactured nanomaterials,” Patricia Holden of the University of California, Santa Barbara, and her colleagues report in one of the studies, published online in the Proceedings of the National Academy of Sciences.

Manufacturers have been turning to nanoparticles in recent years because they perform differently than larger-scale versions of the same product. If nanoscale materials behave differently, both chemically and physically, he asks, “Why should we have assumed they’d behave the same biologically? To study the impact of such materials on crops, Holden’s team exposed soy plants from germination through bean production to soil treated with either of two widely marketed metal-oxide nanomaterials: the cerium oxide used as a catalyst in diesel fuel and other products, or the zinc oxide particles used in sunscreens and as antibacterial agents. Compared to untreated plants, those grown in soil spiked with zinc oxide nanoparticles developed fewer leaves at the highest dose used. By contrast, nano-cerium stunted plant growth at all concentrations, “but most dramatically at the lowest level used,” Zinc oxide accumulated in soy leaves and beans grown in treated soil. Cerium oxide’s entry into the plants, however, stopped at the roots’ nodules. In plants receiving the highest cerium-oxide doses, those nodules didn’t contain the bacteria that normally take the nitrogen from the air and convert it into a chemical form (ammonia) that soy and other crops use as a fertilizer.

The ability of soy and other legumes to fix nitrogen “is one of the most important microbial processes in agriculture,” notes White, an environmental toxicologist. So the ability of nano-cerium to shut this process down “was the most significant new finding” — and the most troubling.

In a second study, published online August 2 in Environmental Science & Technology, White’s team exposed the roots of tomato, zucchini and soy plants to fullerenes, widely used nanomaterials manufactured from pure carbon. Because trace residues of toxic pesticides lace soils long after they were last applied, White’s group looked to see if nontoxic quantities of fullerenes in the root zone affected how plants respond to any breakdown residues of DDT. When fullerenes were present, all three types of plants removed more of the pesticide from the material in which they had been grown — in this case, vermiculite. Since plants were not grown to the fruiting stage, White notes, there’s no way to know if the pollutant would also accumulate in the crop — “but it was certainly in the shoot system.”

Wheat and other small grains, once a staple in the crop rotations on upper Midwest farms, are losing their spot due to market forces and biotechnologies that favor other crops. “Oat acreage is at the lowest in recorded history, and wheat is not far behind,” says Jochum Wiersma, a small grains specialist with the University of Minnesota. “If we're going to maintain any wheat acreage, we will need to maximize grain yield and push the limits.” Wheat does have good value as a rotation crop and for spreading out planting and harvest seasons. Since 1995, yields in northwest Minnesota have gone up an average of 1.6 bushels per acre per year. On a percentage basis, that's as good as or better than corn! he exclaims. To make wheat competitive, Wiersma says you have to select varieties with high yield potential, plant them as early as possible, and manage for maximum grain yield. You also need to produce 14% protein in the grain. Following are the best practices for achieving those goals.

This practice of applying nitrogen late in the growing season originated in Europe about 40 years ago. It is used on bread-grade wheat to boost the protein level into premium ranges. Pre-plant nitrogen is the best way to maximize grain yield. But late-season nitrogen is how you can improve grain protein content, says Wiersma. The most common way to do this is by applying 10 gallons of liquid urea ammonium nitrate (UAN) with an equal amount of water as a foliar application just after anthesis, says Wiersma. Dry sources of fertilizer like urea or ammonium nitrate, commonly used in Europe, haven't been effective in the U.S. The shorter grain-fill period and lower rate of precipitation don't give the crop opportunity to take up the additional nitrogen through the soil. We get anywhere from a 0.5% to 1% higher protein in the grain at harvest this way, says Wiersma. Do not expect all fields to respond equally well. Research has not been able to identify which varieties respond best to the foliar nitrogen. Differences can be attributed to the conditions during and immediately following application, but they don't explain all the variation we observe. We do know that the best time to apply is in the evening hours; the worst time is in the heat of the day with the sun glaring and the winds blowing, he says. Unfortunately, there are no in-season predictors to tell you when it makes economic sense to use UAN to boost protein. Increasing grain protein from 11% to 12% often still means substantial discounts at market. Bringing protein from 13% up to around 14% allows you to avoid discounts as high as $1 per bushel,” he says.

Leaf rust is one of the most significant fungal diseases of wheat, and it is common in upper Midwest fields. Even a 5% severity at anthesis on the flag leaf and penultimate leaf will produce economic yield losses. More serious infestations will reduce yields by 50%. The reddish-brown spores the fungus produces in large quantities can mean that “you have a red combine, even if you bought a green one,” quips Wiersma. Leaf rust is most significant where dew is frequent during wheat jointing and temperatures are mild. That's usually June. Spores are deposited into fields by wind and rain from the winter wheat in the Great Plains. “What plant pathologists describe as the Puccinia pathway, most of us know as Tornado Alley,” says Wiersma. “The southern winds that bring springtime thunderstorms also bring the leaf rust spores. If conditions are right, it develops into an epidemic quickly.” Spring wheat breeders have been successful at providing growers with varieties that are genetically resistant to leaf rust. Unfortunately, one of the resistance genes (called Lr21) that is shared among a number of very popular varieties broke resistance, first in 2010. “In 2011, we saw a recurrence of this and ended up with damaging levels of leaf rust pressure on these varieties, in particular Faller and Prosper,” says Wiersma. “This complicates our fungicide management tactics.”

Research has shown that the optimal time to suppress the other great wheat nemesis (Fusarium head blight) is at the beginning of anthesis. Unfortunately, leaf rust cannot be left uncontrolled that late into the growing season. Consequently, you should scout varieties like Faller for leaf rust when the flag leaf appears. Determine if you need to intervene with a fungicide when the flag leaf is fully extended. The other disease that is gaining ground in wheat country is bacterial leaf streak. It produces translucence in the leaf. If you hold it against your finger, you can see right through it. “It can invade a field when there is physical injury to plants, something like wind damage or tire tracks,” says Wiersma. Although the bacteria can be seed-borne, preliminary research suggests that sanitation will not help control the disease in the field. Fungicides will not control the disease either, leaving variety selection as the best solution. Research is in the process of identifying those varieties, he says.

This practice has come about as growers attempt to get higher wheat yields along with higher protein in the grain. About 20% of the wheat planted in the winter wheat belt of Kansas is blended, where it's done also in an attempt to improve winter survival. “We've done tests where we blended varieties noted for high yields with those noted for high protein,” says Wiersma. “Our results say the performance of blends is equal to the ratio of the blended components. And we didn't overcome the inverse relation of yield to protein; namely, as yield goes up, protein goes down. “Our bottom line is that there is little advantage to blending wheat seed this way in our area,” he continues. “Why not just split the field by variety and then manage and market each of them to their best advantage.”Land and bread: Despite support price, wheat farmers struggle financially Middlemen take advantage of the government’s programmes, leaving farmers stranded.

Scientists from Britain, Germany and the United States have unlocked key components of the genetic code for wheat, helping to create varieties that are more productive and better able to cope with disease, drought and other crop stresses. The identification of around 96,000 wheat genes, and insights into the links between them, comes just two years after UK researchers published the raw data of the wheat genome.

"Since 1980, the rate of increase in wheat yields has declined," said one of the project leaders, Keith Edwards of the University of Bristol. "Analysis of the wheat genome sequence data provides a new and very powerful foundation for breeding future generations of wheat more quickly and more precisely, to help address this problem," he added. "Bread wheat is a complex hybrid, composed of the complete genomes of three closely related grasses. This makes it very complex and large; in total it is almost five times bigger than the human genome," said another of the project’s leaders, Klaus Mayer of Helmholtz-Zentrum Munchen.

"Because of this, we took a novel approach to analyzing the data and we have been successful in turning it into an accessible and useful resource that will accelerate breeding and the discovery of varieties with improved performance, for example, better disease resistance and stress tolerance. The study was welcomed by other scientists. "As we struggle to confront the increasing challenges of population increase, land degradation and climate change that are contributing to food insecurity, it will be vital to understand the underlying genetics of staple crops like wheat," said Denis Murphy of the University of Glamorgan. "The newly published wheat genome will be a vital resource for researchers and crop breeders across the world in their efforts to maintain global food supplies."

If you're holding off planting corn despite the warm spring weather thus far, just don't fill that time with excessive tillage passes through your fields, advises one agronomist. The warm winter and quick start to spring has made it possible to get on top of fieldwork ahead of the normal timeframe. But, that's not always the best situation, says Purdue University Extension agronomist Tony Vyn. If you got your tillage done early but will have to wait until your normal window to plant corn, the time left in between could do more to harm your seedbed than help it.

"From the soil, fuel and time conservation points of view, early tillage operations need to be considered as candidates for the final tillage operations farmers complete," Vyn says in a university report. "It's important not to till now and then do it again later before planting. That means that when farmers are ready to plant, they should consider using a stale seedbed approach. Cloddy seedbed preparation several weeks before planting should not even be considered acceptable, and certainly not on high clay soils."

But, it hasn't just been the 80-degree March and early April temperatures that have been hard on the soil. There weren't as many freeze-thaw cycles over the winter, so that has changed the soil structure. And, if you've got some crop residue and good drainage -- which Vyn says has been the case in much of Indiana through early spring so far -- you could actually lose soil moisture quicker. So, if you're on the west side anyway, this spring might be a good year to plant into a minimum- or no-till system. "This spring weather is not only speeding up tillage, but it's making it more likely that no-till operations can occur in a more timely manner," Vyn says.

"There will be less delay associated with planting into higher residue. However, chemical weed control needs to be timely in a spring with such early weed pressure to maintain the no-till option." Tillage isn't the only spring job on which timing is critical. It's also a good idea to try to keep your spring fertilizer applications as close to planting as possible, as the wider the window between application and planting, the more apt you are to lose some of what you put down. "By applying anhydrous ammonia now, there is a clear time separation between application and planting. That means less likelihood of zones of high ammonium concentrations potentially interfering with early seedling corn growth," Vyn says. "However, it's a trade-off, because with early applications, mineral nitrogen has to stay in the soil longer for it to be available to plants."

High grain prices, high input costs and better than average yields add up to a lot of risk. As a result, it’s vital to devise a storage strategy ahead of time to avoid insect and moisture damage. The place to start is a thoroughly cleaned bin, whether it’s a flat bottomed grain bin on wood, steel, asphalt or concrete or a hopper bottomed unit. Brent Elliot of the Canadian Grain Commission said it’s tempting to take hopper bottom bins for granted by not removing all of the grain and sweeping out accumulated dust.

Insects can survive in even small amounts of cereal grain that is left in a bin,” he said. “If the bin has a fan and aeration system for drying, that can get grain inside it, in tubes. Insects can be lurking in there.” Saskatchewan Agriculture entomologist Scott Hartley said producers must avoid creating habitat for insects such as the rusty grain beetle, which is the Prairies’ most common grain pest. In some areas, the foreign grain beetle and red flour beetle can also be problems. Elliot said producers can use high pressure water or air to ensure their bins are clean, but this method requires caution. “They also need to be dry, so with water you need to make sure they get a chance to air out if you use water.”

Hartley said producers may use insecticides such as malathion to treat their bins, but this is only allowed for cereals. Other crops, such as canola and flax, absorb the pesticides and will potentially breach internationally acceptable maximum residue limits for trade.

“It can be useful for older bins (for cereal storage), where getting it really, really clean is an issue. Or where you suspect there might be a problem.” Elliot said grain should be as flat as possible at the top of the bin to avoid uneven moisture concentrations. “I know that can be a challenge and we don’t advocate climbing into the bin to do it, but where it can be done it can help, especially if you are storing it for a longer time,” he said. Grain is an excellent insulator and will develop its own air currents that circulate throughout the bin. While this means the air will remove moisture and energy from grain in one area, it will also deposit it in another, creating hot and moist grain pockets. Hartley said that is an ideal environment for insect development.

“We’ve had great harvest conditions for the most part. Hot days,” he said. “Grain is dry and you put it away in the bin and two months later you have spoiled grain and bugs.” This happens because of air movement within the bin. The cooler bin sides cool grain, and the air falls on the outside and rises in the still hot core. These convection currents help water vapor migrate to the cooler walls and bin roof, where it condenses and eventually meets grain. Heat also encourages fungal growth, provided there is moisture, which creates more insect habitat. The grain should be aerated or cooled to less than 15 °C as soon as possible if the moisture content is less than 14.5 percent. Reducing the temperature to 18 °C, provided it is dry, generally renders it safe for storage.

“Bugs don’t do a lot of feeding or growing below 15 degrees,” Hartley said. “Luckily, winter will come and the grain will get there, provided it hasn’t started to heat.” Grain monitoring cables can be placed in the bin before loading. These can give readings on temperature conditions within the bin. The grain’s convection currents will be minimized when the temperature gradient has stabilized within the bin, and the grain will store safely. The grain commission recommends checking stored grain every few weeks until it can be reasonably assumed that the grain is dry and the temperature stable. Grain vacuums are effective tools for killing insects at any stage of development. Diatomaceous earth is also effective, especially when added preventively to dry grain as it is placed in storage at harvest. Malathion is also effective when added to grain as it is transferred. Phosphine, carbon dioxide and a combination of the two can be used to fumigate bins with insect problems. Chlorpyrifos, diazinon, dichlorvos, dimethoate and other insecticides such as pyrethrins are registered for use to prevent insect development when treating corners and hard to clean areas.

Findings point to treated corn seed — and corn syrup — as possible links to a pandemic afflicting North American pollinators.

A pair of recent papers indicted neonicotinoids, a widely used class of insecticides, for contributing to a catastrophic decline of honeybees, especially since 2006. Hives across North America have been hammered, many by a particularly mysterious syndrome known as colony collapse disorder, or CCD. Now an additional field trial strengthens even more the case arguing that these pollinators have been poisoned by these chemicals. This latest research also points to a potentially novel source of the chemicals: corn syrup.

Threats at home hives should offer bees security. But they could prove a threat if the sugary nectar brought home is tainted. CCD tends to occur in winter or early spring, often when bees begin their first foraging trips of the year. In affected colonies, bees leave but fail to come home, despite their hives having adequate food. One suspicion, which is supported by studies, is that pesticides or some other poison might impair a forager’s memory or behavior. But Chensheng Lu, an environmental scientist at the Harvard School of Public Health in Boston, was puzzled as to when and where the critical exposures occurred. After all, affected bees were disappearing after months without exposure to toxic agents outside the hive. Lu now argues that bees can undergo a chronic poisoning if their hives’ honey was tainted by insecticides that the pollinators encountered months earlier. Bottom of Form During winter, he charges, what looks just like colony collapse disorder largely emptied 15 of his team’s 16 test hives in central Massachusetts.

Each had been exposed experimentally for 13 weeks during the summer to low doses of imidacloprid. Growers rely on this and related neonicotinoid insecticides to protect their crops.

How long a hive’s colony survived after treatment diminished with increasing exposure of its bees to the insecticide the previous summer, Lu and his colleagues reported online April 5 in the Bulletin of Insectology. Among four untreated hives, three survived. The other perished, but from dysentery — an intestinal infection — not CCD.

For their experiments, Lu and his colleagues set out groups of five hives, each consisting of healthy commercially purchased honeybees. The experiments were carried out in quadruplicate, with each grouping of five hives sited at least 12 kilometers from another. Insects at each site could forage throughout the wilds. The researchers also provided each hive with the equivalent of its own on-site fast-food restaurant: a plastic feeder containing high fructose corn syrup. Bees apparently love the sugary drink. Indeed, Lu says, many apiarists regularly feed this inexpensive beverage to their colonies in late winter to compensate for any overharvesting of honey (wintertime grub for bees). One hive at each test site got corn syrup free of imidacloprid. The rest each got access to syrup containing small additions of the pesticide.

Depending on the hive, syrup concentrations of the chemical ranged from 20 to 400 parts per billion. These values were all below federal limits for the pesticide in corn, Lu explains. Offering hives corn syrup allowed the scientists to precisely doctor each batch with known quantities of the test chemical. It also allowed Lu to explore a hypothesis: that bees might be seriously impacted if even small quantities of neonicotinoid chemicals find their way into corn syrup. And they might, he argues. Commercial beekeepers have been disproportionately affected by hive losses. One of the few changes they’ve made to insect husbandry in recent years has been to supplement hives with corn syrup during winter months. Although that began prior to 2006, what did almost precisely coincide with the initial outbreaks of CCD was the emergence of widespread commercial treatment of corn seed with neonicotinoid insecticides.

In North America and parts of Europe, many seeds now are coated with neonicotinoid insecticides before planting. As seeds germinate, the chemical enters the plant and circulates throughout its tissues, protecting vulnerable roots. This systemic circulation of the pesticide bolsters concern by Lu’s team that imidacloprid can move into corn kernels. If it does, then the chemical could end up tainting corn syrup. Today, imidacloprid or one of its neonicotinoid cousins coats most conventional and virtually all genetically modified corn seed, notes Charles Benbrook, chief scientist at the Organic Center in Troy, Ore. That’s troubling, he argues, because in terms of their impact on bees, neonicotinoids “are the most acutely toxic pesticides ever registered.” They are also moderately persistent in soil, he says. And in recent years, insecticide-based seed coatings have tended to use a controlled release formulation. This extends crop protection benefits, Benbrook says, “but it also extends the time during which residues from seed treatments are likely to persist in treated plants.” Like Lu, he suspects these insecticides can get into corn kernels — and the corn syrup now frequently fed to bees (something Benbrook’s organization has attempted to assay, unsuccessfully). But there are plenty of other routes by which bees can become exposed to these chemicals, Benbrook notes.

He points to data showing that plants from treated seeds can “sweat out” minute quantities of the insecticide into morning dew, a beverage popular with bees. Detectable quantities of imidacloprid have also been measured in the pollen of corn and sunflower plants whose seeds had been treated with the chemical. And European researchers have documented some seed planting equipment that roughs up seeds, generating an airborne exhaust cloud containing insecticide-laced residues. In light of such data, including Lu’s new paper, Benbrook concludes that “there’s strong evidence that [neonicotinoid] seed treatments are putting pollinators at risk around the world.” But treated seed is hardly bees’ only possible source of exposure to these chemicals. Even five to seven years ago, Benbrook points out, 70 percent of U.S. apples, 79 of pears and 40 to 50 percent of broccoli and cauliflower were treated with these insecticides.

Not everyone is convinced by the Massachusetts field trials. Louisa Hooven, a beekeeper and scientist at Oregon State University in Corvallis, says that based on the sketchy observations described in the new paper, she finds it hard to be sure that the authors have indeed replicated CCD. For instance, “the presence of dead bees in front of the hives [reported by Lu’s team] does not resemble CCD,” she says. “In CCD, no bees are found.” And certain characteristic symptoms of the syndrome went unmentioned in Lu’s report. She says this includes whether the queen and some of her attendants remained behind even after most adult bees had fled the hive, as often occurs with CCD. Or whether there were signs of sealed pollen, which has also been associated with a hive’s collapse. To indict imidacloprid, she’d also like to see the researchers get a solid gauge of how much of the insecticide the bees had actually carried into the hive and then consumed.

At the Society of Toxicology meeting in March, Hooven presented some of her own data from preliminary experiments in which she exposed bees to pesticides. She administered low-dose concentrations of three chemicals to clean hives. All three pesticides are among those that have been measured tainting North American honeybee hives. After a few weeks of living with the chemicals,Hoover saw no deaths But the queens’ egg laying behavior was perturbed and the maturation of nurse bees exhibited a delay. Such subtle but potentially important changes also highlight one problem facing any environmental scientist sleuthing the putative mechanisms for CCD: Most bees simply aren’t exposed to just one toxic chemical. A 2010 study by scientists from around the United States quantified 121 different pesticides and their breakdown products that they had isolated from bees, pollen, wax and other hive materials. The average number of pesticides identified in wax: eight. Among 350 pollen samples retrieved from hives, each harbored an average of seven such chemicals — but at times up to 31 pesticides (or their breakdown products, some of which are more toxic to bees than the parent chemical).

Winter wheat isn't just limited to the Great Plains and eastern and central Corn Belt states. It's gaining appeal in traditional spring wheat-growing regions like the Dakotas and Minnesota. “It can spread out workload for the farmer and provide cover over the winter. “Winter wheat in the Dakotas traditionally yields 10 to 15 bushels per acre more than spring wheat,” he says. It also fits a niche for planting prevented planted acres that have plagued upper Midwest farmers.

The downside? Fusarium head blight (scab) can plague winter wheat more than in spring wheat. “Protein levels aren't as high,” says Wrucke. That can dash hopes of garnering protein premiums that add up to $1 per bushel in additional price. Bayer is partnering with Ducks Unlimited, industry, and several land-grant universities in an upper Midwest winter wheat research and education initiative. Here are six recommendations garnered so far to successfully grow winter wheat.

Soybean and corn crops in Ontario are yielding better than expected, according to industry officials. “We had quite a dry summer in Ontario so there were considerable concerns that the yields were not going to be there,” Horst Bohner, soybean specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs said. “But on the whole the yields were better than expected.” Bohner said because conditions varied so greatly across the province, the range of yields for soybeans that were reported as of late October was “tremendous.”

“Some acres really did have severe dry conditions so we’ve heard of yields as low as 15 bushels per acre and as high as 80 bushels per acre,” he said Corn yields were also showing a wide range due to differing weather conditions. Greg Stewart, corn specialist with the Ontario Ministry of Agriculture said reports of yields as low as 30 bushels per acre and as high as 260 bushels per acre had come in as of October 25.

Most corn and soybean growing regions did experience dry weather, but some were lucky enough to receive one or two timely rains that made the difference at harvest time, Bohner said. As of October 25, harvest progress across the province as a whole was about 80 per cent complete for soybeans, and 50 per cent for corn. Though, some regions were more or less advanced than that. “As we got into harvest there was a good run at the crop in terms of harvesting and then it started to rain,” Bohner said. “So, in the north, the harvest isn’t that far along, and in some of the areas that caught a little bit more sunshine, harvest is more advanced.”

The better than expected yields will probably entice Ontario’s producers to plant another record sized soybean crop in the spring, Bohner said. Farmers across the province planted 2.65 million acres of soybeans in 2012/13 (Aug/Jul), the latest Statistics Canada production report said. Strong soybean prices will also help to influence producers to plant more soybeans for the 2013/14 crop year as well, though a lot of it will depend on corn prices and how much winter wheat is planted this fall, Bohner said. Stewart noted it is still a little early to predict what corn acreage will be in the 2013/14 crop year, as it will also depend heavily on how much winter wheat gets put into the ground.

The rains that fell over much of the central U.S. have dried out enough to allow farmers to get back into the field and resume what so far has been a jump-start to the crop season. It's been quite an anomalous year so far in corn and soybean country. There's corn already out of the ground in parts of Iowa and Illinois, and those who haven't planted yet are getting a lot of fieldwork knocked out early. So what, if any, effects will the early progress have on your corn yield potential once the combine rolls this fall?

Though there have been a lot of warnings about the potential drawbacks of planting corn well ahead of schedule even when the weather permits, the sooner the seed's in the ground, the lower your chances for a yield hit compared to late-planted corn, says University of Illinois Extension agronomist Emerson Nafziger. "The yield response indicates a slight yield advantage for corn planted in mid-April, but a generally very flat yield response for corn planted between early April and early May," he says. "In contrast, there is a yield penalty associated with corn planted later than early May, with increasingly large penalties as planting occurs after mid-May."

What's most notable from the research behind this conclusion, Nafziger adds, is it disproves a common misconception about yield potential and early planting. Instead, it's more of a preventative measure to avoid losses from having to wait beyond the optimal planting window. "Contrary to popular opinion, this research indicates that there is not a substantial yield premium for early planting, but confirms that there is a notable yield penalty for late planting," he says. "The potentially beneficial impact of planting a large portion of the crop early, then, is in the avoidance of the yield penalty of late planting."

Future historians may well look back and write about our time …. about how willing we are to sacrifice our children and jeopardize future generations with this massive experiment that is based on false promises and flawed science just to benefit the “bottom line of a commercial enterprise,” said Don Huber, referring to the North American “experiment” with glyphosate and genetically modified crops. He was speaking at November’s Organic Connections conference in Regina.

He is an emeritus professor in plant pathology at Purdue University, a retired colonel who worked with the U.S. Department of Homeland Security to reduce the impact of plant disease outbreaks in the United States and a member of the emerging diseases and pathogens committee of the American Phytopathological Society. He has the usual markers of academic success: journal articles, books, awards and honors. In other words, he is a real scientist with the ability to read the scientific literature and weigh its impact, especially in the area of his expertise: plant diseases. Huber began his presentation by describing glyphosate as a chelator, something that binds with a number of nutrients such as manganese, zinc, copper, and iron. Once a nutrient is chelated, it is unavailable to the plant, or for that matter, to most soil microbes. He said it is through a change in the soil ecology, and by disabling the plant’s ability to resist disease, that the glyphosate has its effect.

“In agriculture, we’re farming ecology,” he explained. Glyphosate changes the soil ecology, killing many bacteria, and giving other bacteria a competitive advantage. It also makes plants highly susceptible to soil borne diseases. With increasing use of glyphosate, Huber said a number of plant pathogens are “emerging” or “re-emerging,” including a number of fusarium and root rot diseases.

At the same time that diseases are increasing, glyphosate has a negative effect on a number of beneficial soil organisms, including those that fix nitrogen, mycorrhizae, plant growth promoting organisms and earthworms. Huber’s allegations of the impact of glyphosate in soil sterility echo those of Elaine Ingham, a soil ecologist with the Rodale Institute. In insect and microbial communities, ecologists generally suggest that epidemics can be avoided by a balanced ecology. Beneficial organisms tend to overwhelm pathogenic organisms in a healthy system. This is why some suggest it is useful to eat yogurt after a round of antibiotics, and that antibiotic body products are probably not a good idea.

Local evidence is supportive of this idea. Myriam Fernandez, a plant disease specialist with Agriculture Canada, found that fusarium in organic systems tended to be dominated by saprophytic species (not disease causing) whereas pathogenic fusarium (causing disease) were more abundant in other systems where GM crops and glyphosate were commonly used. “There is nothing substantially equivalent to gene insertion in nature,” Huber said. He said he worries about the possibility of epigenetic effects that disrupt the normal control systems of the genes in the plant. He said the GM crops had lower water use efficiency and less tolerance to lodging, tend to be nutrient deficient, have increased bud and fruit abortion and be predisposed to infectious diseases and insect damage. These he characterized as epigenetic effects. Huber feels the application of phosphorus fertilizers could release the glyphosate in the soil so that it becomes active once again, damaging crop yields.

If all these problems are in fact linked to glyphosate and Roundup Ready crops, why are we not hearing of widespread crop failure? Introduction of GM crops into India is said by some to have delivered these effects. Perhaps in North America these effects are overwhelmed by increased fungicide and insecticide use? In many places on the Prairies, it would be hard to separate that from the effect of too much rain at the wrong time. As in any ecological disturbance, many factors are bound to be involved. Huber suggested that Roundup Ready crops, treated with glyphosate, had higher levels of mycotoxins and lower nutrient levels than conventional crops. When consumed, the GM crops were more likely to cause disease, infertility, birth defects, cancer and allergic reactions than conventional crops.

Huber claimed that consumption of food or feed that was genetically modified could bring the altered genes in contact with the microbes in the guts of the livestock or people who ate them. He felt this increased diseases such as celiac disease, allergies, asthma, chronic fatigue syndrome, diabetes, gluten intolerance, irritable bowel disease, miscarriage, obesity and sudden infant death syndrome. Much of the data Huber showed here seemed correlational: the diseases and the use of glyphosate increased in a similar pattern over time. This isn’t proof that the diseases are caused by the glyphosate, but it suggests a pattern to be investigated. He feels safety evaluations have been inadequate, suggesting that research was “substandard and extremely misleading interpretation of results” or worse. Because of difficulties for independent researchers to examine the licensing agreements for GM products, third party opinions are hard to come by.

The allegations that Huber has compiled are incredibly damning of GM products and the inherent increase in glyphosate that goes with the Roundup Ready products. Those people who have confidence in the wisdom of our governing and regulating bodies will find these stories hard to believe. Some will suggest that science has shown these technologies to be safe. That would be misinterpreting the science. Unfortunately, science cannot prove a technology is safe. It can only fail to observe a problem under the conditions of the test. Perhaps scientists fail to observe a problem because none exists. If even a small part of what he suggests is true, we would be well advised to reconsider the policy of treating GMOs as “substantially equivalent” to non-GM products and instead, investigate the technology further. In the meantime, some of us may wish to avoid products using this technology. Some may claim this is fear mongering. If this is, in the end, a subject upon which we must agree to disagree, labeling of GM products would at least give us the ability to disagree in a meaningful way.

Court instructs FDA to resume efforts aimed at banning use of low-dose antibiotics in livestock feed. In 1950, Science News ran a story showing for the first time that a potent antibiotic could do more than knockout disease. New animal experiments, we reported, “cast the antibiotic in a spectacular new role” as a livestock growth promoter. Lacing the food of hogs with trace quantities of this drug increased meat yields by up to 50 percent, scientists at Lederle Laboratories had reported at a research conference. Sixty-two years later to the day, a federal judge has now ordered the Food and Drug Administration to resume efforts toward outlawing this nonmedical use of antibiotics. The 1950s were rife with ebullient prognostications. And our reporter back then had found the prospect of boosting meat production with harmless quantifies of a drug exciting. Our story proclaimed that the discovery “may hold enormous long-range significance for the survival of the human race in a world of dwindling resources and expanding populations.”

But it turned out that here, as in so many instances, there’s no free lunch. Feeding animals trace quantities of an antibiotic didn’t harm them. In fact, it launched the widespread and largely indiscriminate use of these life-saving drugs for nonmedical purposes. As germs encountered subtherapeutic doses of these medicines again and again, both in animals and the environment, bacteria evolved a resistance to them. Bottom of Form Before long, that resistance began emerging in humans who became infected with the same germs, or close relatives to them. The result: As in the 1930s, people were again facing life threatening illness from germs that antibiotic wonder drugs had been developed to eradicate. FDA knew about this, of course, notes U.S. Magistrate Judge Theodore Katz in his new ruling. Thirty-five years ago, he points out, “FDA issued notices announcing its intent to withdraw approval of the use of certain antibiotics in Livestock for the purposes of growth promotion and feed efficiency.” At that time, FDA acknowledged that nonmedical use of penicillin and tetracycline-type drugs and the drug resistance they were spawning — threatened human health.

By law, that 1977 ruling should have set in motion a procedure of hearings that would give drug manufacturers a chance to rebut the FDA assessment. If the drug makers didn’t challenge the assessment or prove that FDA had gotten it wrong, growth promoting use of the drugs would have to end. But those hearings never took place, which has given livestock growers a 35-year extension of the drugs’ use. Enter the Natural Resources Defense Council. Last year, its litigators filed a lawsuit against FDA on behalf of the Center for Science in the Public Interest, Food Animal Concerns Trust, Public Citizen, and the Union of Concerned Scientists. These public-interest groups charged that FDA dropped the ball and the public was suffering. They asked the court to make FDA resume its procedural case against antibiotics in livestock feed.

For its part, FDA argued that it was in the process of working with drug manufacturers to encourage a voluntary phase-out of growth-promoting applications of penicillin and tetracycline antibiotics. So the agency argued it no longer needed to formally outlaw these uses. Not true, argues Judge Katz in his March 22 opinion. The law is the law. Once FDA made a preliminary determination that human health was imperiled by nonmedical antibiotic uses, the process must progress toward a formal withdrawal of legal approval for this application. As long as the initial science has not been proven wrong in the interim, the agency is obligated to complete the action it started even after 35 years. Indeed, the judge observes, over the intervening decades “scientific evidence of the risks to human health from the widespread use of antibiotics in livestock has grown.” Those health concerns and accumulating libraries of data also point to risks for antibiotics that extend well beyond the penicillin and tetracyclines covered in FDA’s 1977 assessment. In fact, two citizen petitions asked FDA to end growth-promoting uses for additional antibiotics.

Last year, FDA threw out the petitions, arguing they were moot now that the agency was working with drug manufacturers towards some sort of voluntary phasedown or phaseout. Arguing that voluntary guidelines will not satisfy these claims either, “We’re challenging the denials of those petitions,” says Avinash Kar, one of the NRDC attorneys involved. “So that part of the case is still being litigated,” he says, “and will probably result at some point in a court hearing.” For now, Judge Katz has merely instructed FDA to go ahead and hold hearings on the fate of penicillin and tetracycline. How soon the agency must act has not yet been spelled out, Kar says: “Further court proceedings will decide the timeline. And, of course, it’s possible that FDA might appeal.”

Barley and red lentil producers in Western Canada have recently seen several changes to the way their crops are graded and classified. Last week, the hulless barley class was eliminated from the Official Grain Grading Guide and a new food barley class was added. The changes were recommended by the Western Standards Committee earlier this year and would take effect at the beginning of the new crop year, said Darryl Beswetherick, program manager with the Canadian Grain Commission. The existing classification system divides barley into three classes: malting, hulless and general purpose.

The hulless class was removed and a new food class was added. Beswetherick said the changes help the industry promote new barley varieties that have good milling characteristics and were developed specifically for specialty food markets. “By having the new food (classification), we can now put the title No. 1 Select Food onto certificates,” he said. “Certain varieties which are bred specifically for food use can now be marketed and graded accordingly.” Although the market for food barley is small, the Canadian industry expects more barley to be used in products such as soup, bread, bakery products, teas and sochu, a Japanese distilled beverage. The industry is eager to capture that added value and has been pushing for the new food barley classification to help with marketing and promotion.

Canadian barley breeders have already developed and registered promising new varieties that can be used for food or milling, including CDC Rattan, CDC Fibar and CDC Hilose. Health authorities in the United States have also authorized a health claim that can be attached to the labels of food products containing barley. The Canadian barley industry is hoping Health Canada will support a similar claim, which would further support efforts to promote and market specialty barley varieties. Unlike the malting barley classification, the new food barley class does not have a list of designated varieties.

Malting barley has a designation list that stipulates which varieties can be used for malt. “We aren’t going to have a designated list for food barley,” Beswetherick said. “The reason for that is that the market will decide which varieties will go into that class.” The grain commission also announced grading changes that took effect for red lentils on Aug. 1. New grading tolerances were added for copper coloured, bleached and wrinkled seeds, which can affect the dehulling process and are therefore less valuable to lentil processors.

Under the new grading system, No. 1 Canada red lentils must contain no more than one percent copper-coloured seeds and no more than three percent bleached and copper-coloured. Maximum tolerances for No. 2 samples are three percent copper and 10 percent copper and bleached. Samples that exceed those tolerances will be downgraded to Extra No. 3 or No. 3. New wrinkling tolerances have been set at two percent or less for No. 1 Canada and five percent or less for No. 2 Canada. Wrinkling tolerances are not being applied to Extra No. 3 or No. 3 grades. Garth Burns, a Saskatchewan lentil producer who chairs the Western Standards Committee’s pulse group, said the new tolerances bring Canadian grading standards in line with standards established in other countries. However, they also make it more difficult for Canadian growers to qualify for the top two grades. “This means that the bar now is somewhat higher for us to jump over and we may not see … that top grade as often as we’ve been accustomed to in the past,” said Burns, who farms near Drake, Sask.

“Our direction was to bring our grading more in line with that of our competitors…. That’s what this new grading specification reflects and it was not in my favor, but on the other hand, I know we have to trade with the same standards that they use in other countries.”Burns said the new grading standards are likely to affect red lentil acreage in the province. The price spread between No. 2 and No. 3 is often as high as six cents a pound, which is likely to discourage production. “It’s always nice to get in that top grade or two and get rewarded for it, so yes, this is going to tighten the belt a bit,” he said. “It’s going to take the cream away from the top, that’s for sure.” For more information, visit www.grainscanada.gc.ca/index-eng.htm and click on the link entitled What’s New.

Demand for local food products is no longer limited to fruits, vegetables, and honey. Regional artisan bakers are teaming up with their area's farmers and millers to provide customers with locally produced breads. While still a unique concept in the U.S., European countries, such as Italy, have always celebrated breads and pastas made from locally grown grains. They appreciate the distinctive flavors and freshness.

“With the emergence of the Foodie Culture, more consumers in the U.S. are demanding and paying a premium for flours that are regionally distinctive,” says Steve Voight, president and chief executive officer of King Arthur Flour, a 220-year-old flour milling company based in Norwich, Vermont. The company's history dates back to a period when New England was the nation's breadbasket. After the Erie Canal was built, wheat shipped out of the Midwest grew from 14,000 bushels in 1826 to 8 million bushels in 1840. New England grain production could no longer compete with Midwestern wheat and declined accordingly. With a strong commitment to its own history, King Arthur is now a leader in the movement to bring back local grain production. “What we are seeing is that these grains grown in Maine and Vermont have qualities distinctly different from ones grown elsewhere,” says Voight.

Voight says distinguishing grains by region is not new. In many ways, it mirrors the French concept of terroir – a view held by winemakers that the soil and climate of a region bestow a unique flavor signature on the grapes grown and the wine produced in that region. One artisan baker and innovator to incorporate this philosophy into his successful business model is Mike Dash, owner of Rolling Fire, a Seattle-based catering service specializing in authentically crafted wood-fired pizzas. After years of study, Dash concludes that locally grown grains, milled fresh to a pizzeria's specifications, are an essential element in building an extraordinary pizza. “This is something we are now learning in the Northwest,” he says. “When we connect directly with local grain farmers, the obvious outcome is an improvement in what we have to work with.”

But quality, flavors, and freshness of the end product aren't the only reasons why locally produced wheat has become such a hot topic for bakers and millers, says Steve Jones, veteran wheat geneticist and director of Washington State University's Mount Vernon Research Station. He points out that in recent years, grain speculation has lead to major fluctuations and even outright wheat shortages in some parts of the U.S. “In 2008, a bushel of wheat that normally would go for $4 to $8 (per bushel) rose to $25,” says Jones. “Some bakers went out of business because they couldn't afford the flour.” In response, artisan bakers across the country are now working directly with local growers and millers to make sure their grain and flour supply keeps flowing.

In September 2011, the Mount Vernon Research Station, located north of Seattle, hosted the first annual Kneading Conference West, a three-day event that is a direct offshoot of a successful Kneading Conference started in Skowhegan, Maine, in 2007. This is a national movement that has emerged through necessity, says Amber Lambke, one of the founders of the original Maine event. “These conferences are a way to bring everyone who has a vested interest in the future of local wheat production together in one place,” she says. Lambke's participation in the founding of the Kneading Conference is a direct result of her involvement in the conversion of an 1863 county jail in her adopted hometown of Skowhegan into a community-based grist mill for the purpose of grinding locally produced grain. “We could see there was a need to share information between communities involved in similar projects,” says Lambke, noting that Skowhegan was an appropriate setting for a local wheat conference. It was the hub of an agricultural region in the 1830′s that produced enough grain to feed 100,000 people. “The level of knowledge circulating at these events is remarkable,” says Lambke. “They are really a crash course on how to set up local grain networks.”

Two Oregon residents who have successfully forged a farm-to-bakery working relationship are David Mostue, comanager of Dunbar Farms of Medford, and Ben Casder, owner and operator of Sun Stone Artisan Bakery in Ashland. Mostue's family has been farming the same 230 acres since his grandfather purchased the property in 1909. Originally a pear orchard, Mostue has expanded the family farm's production base well beyond fruit. He now farms 5 acres of wine grapes, 90 acres of hay, 30 acres of orchard fruits, 30 acres of grain, and 6 acres of row crops. “It is relatively arid in our part of the state, so we have ideal growing conditions for wheat and legumes,” says Mostue. The wheat is grown and milled on-farm, shipped to Casder's Sun Stone Artisan Bakery, crafted into bread, and then sold through local retail outlets. “What really makes it work for Ben and I is that we share the same views on the importance of locally produced foods,” says Mostue. “It all makes it worthwhile when I can pick up a loaf at the local grocery and know that it is made from wheat grown and milled on our farm.”

Looking to snap up your corn yields for 2012? Here are some factors to consider for this year and beyond.

University of Minnesota (U of M) trials from 2007 to 2011 showed 60- to 90-bushel differences between the highest- and lowest-yielding hybrids. “No other agronomic practice influences yield as much,” says Jeff Coulter, U of M Extension agronomist.

Longer-maturing hybrids yield more than shorter-maturing ones because they produce more kernels. U of M scientists compared three maturity groups at three southern Minnesota sites from 2006 to 2010. The late-maturing group of 103- to 107-day hybrids had a 5% yield edge on the 93- to 97-day hybrids. Meanwhile, the yields of 98- to 102-day hybrids edged those of the 93- to 97-day hybrids by 2%. Still, yield difference is not sizable when compared with the huge gap between hybrids in the 2007 to 2011 study. What yield edge you do glean is tempered by increased harvest moisture, says Coulter. Harvest moisture for 93- to 97-day hybrids was 17.2%, 18.4% for 98- to 102-day hybrids, and 20.2% for 103- to 107-day hybrids.

Timely planting is essential for top yields. Still, don't sweat it if short delays result. The wait for better soil conditions may be worth it. In southern Minnesota, the best time to plant corn is between April 21 to May 6, says Coulter. Still, U of M trials show yields for corn planted in mid-May rivaled mid-April plantings. Averages from 2008 to 2010 at two sites found just a 2% yield loss for corn planted in mid-May compared to late April. Yields started slipping when planting was delayed beyond mid-May. Yields were 15% of what they were for corn planted in late April.

“There is little yield loss when planting is delayed until mid-May,” says Coulter. “There is rapid yield loss when planting is delayed beyond mid-May.

Seventy-five-bushel spring wheat is way above average, but it's still a reasonable goal 150 miles north of Canada's Devil's Lake, according to Cornie Fehr. “Five years back, I would have been happy with 50, 55, 60 bushels per acre. But I do my inputs differently now, so I expect more,” the Canadian says. Fehr plants his spring wheat near Arden, at the center of Manitoba's farming industry, where red spring wheat average has yielded about 45 bushels per acre since 2006.

Fehr grows 3,100 acres of hard red spring wheat in a tight two-year rotation with canola. He uses conventional tillage. “If I get the right weather conditions (in 2012), I'm sure I could grow 65- to 75-bushel wheat,” he says. Last year was almost hopelessly wet, but on the fields that didn't drown, Fehr estimates his yields came in at around 70 bushels per acre. Back in 2009, the last season with good growing conditions, Fehr had whole fields of red spring wheat that yielded 80 bushels an acre and more. It's a challenge, he says, to keep a +70-bushel wheat crop from lodging. Several years ago, he changed to a high-yielding shorter wheat with strong straw. It's better, but it still can lodge after a heavy rain.

Fehr has about eight steps in producing that kind of yield, but he believes the single biggest impact is coming from fungicides and micronutrient products. He began using nutrition and disease-protection products on his wheat just a year or two before the 2009 record. “I think the seed primer and the top dressing, and the way I fertilize with deep-banding the nitrogen and potash have had the biggest impacts on my wheat yields,” Fehr says. “I do a little top dressing with nutrients and fungicides.”

Fehr's field plan includes the following eight steps to achieve that 80-bushel-per-acre yield, using two air drills and a high-clearance sprayer, if conditions are right.

Assuming the crop is clean and the weather is cooperating, Fehr says even better yields are possible if scientists come up with genetics or chemistry to neutralize fusarium head blight (scab) in tomorrow's wheat.

Herbicide-resistant weeds are here to stay. The most recent summary indicates that 450 unique cases of herbicide resistance —encompassing 245 species — occur globally. Approximately 11 to 12 cases of unique resistance are discovered each year, says Aaron Hager, Extension weed specialist at the University of Illinois.

But there's good news. Tools and strategies are available to help you stay ahead of those pesky weeds and halt their spread. However, the rapid planting that occurred this spring may have given weeds a head start. "The rapid progress of corn planting sometimes can outpace the application of soil-residual herbicides," says Hager. "In most instances these herbicides are applied within a few days after planting, but weather- and equipment-related factors can delay applications until after corn has emerged." If you find yourself in a similar situation, look at the label. "Labels usually indicate a maximum corn growth stage beyond which applications should not occur," adds Hager. "These growth stages can range from as early as two leaf collars to as late as 40-inch-tall corn, so be sure to consult the respective product labels. Products containing atrazine must be applied before corn exceeds a 12-inch height, although the labels of some atrazine-containing products specify a shorter height."

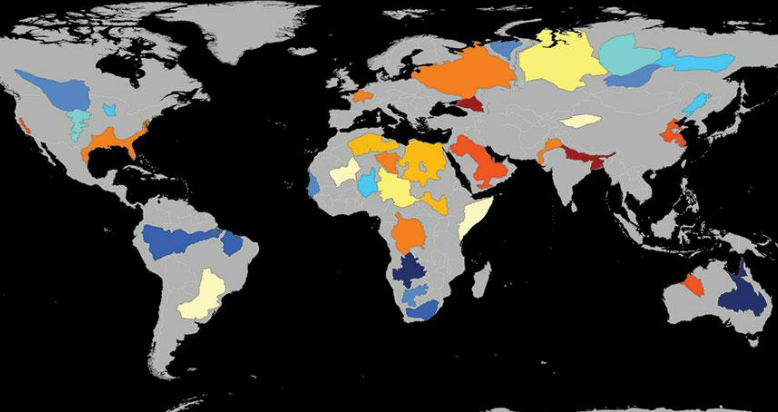

Climate and human consumption are parching Earth’s groundwater basins at an alarming rate, a new study finds. Of Earth’s 37 biggest groundwater basins, 21 now lose more water annually than they take in, researchers report in a paper to be published in Water Resources Research. That’s troubling, says study co author Sasha Richey, a hydrologist at Washington State University in Pullman. Groundwater quenches the thirst of about 2 billion people, provides irrigation for crops and helps keep wetlands wet.

“People need to think about groundwater as an important resource,” Richey says. “We’re not managing that resource adequately, or even at all, in most of the world.” Scientists typically monitor groundwater reserves using wells, but this method fails to provide the global picture of how water levels are changing. Richey and colleagues instead used data collected by GRACE, twin NASA satellites that measure small changes in Earth’s gravity. As water pools underground, the satellites record a stronger gravitational tug. The researchers examined gravity changes measured from Earth’s largest aquifers from 2003 through 2013. Eight of the studied aquifers lost significant water over the decade and were classified as overstressed, with nearly no natural water replenishment to offset withdrawals. The regions of greatest concern were the Arabian Aquifer System in the Middle East, the Murzuq-Djado Basin in northern Africa and the Indus Basin in northwestern India and Pakistan.

The most dried-up aquifers commonly had large populations nearby, substantial local agriculture or an arid climate. All three factors probably contributed to the California Central Valley Aquifer System rating as extremely stressed, Richey says. California’s groundwater withdrawals have skyrocketed recently in response to the state’s ongoing drought. While GRACE provides valuable information about how global groundwater has changed, it can’t measure exactly how much water is left in the aquifers, says Gordon Grant, a hydrologist at the U.S. Department of Agriculture Forest Service in Corvallis, Ore. Despite that shortcoming, the new work “allows us to put our arms around the volumes of water that are in play and better understand, like an accountant would, withdrawals and deposits of groundwater around the world,” he says.

Cool weather and wet soil conditions throughout areas in the Midwest have disrupted the normal sequence of early season field operations. One of those happens to be pre-emergence herbicide applications.

The application of soil residual herbicides is important because usually they deliver several weeks of weed control, cover a broad spectrum of weeds, and aid in weed resistance management by incorporating additional site(s) of action, say Amit Jhala, Extension weed management specialist at the University of Nebraska-Lincoln, and Lowell Sandell, Extension weed science educator.

“This year many Nebraska cornfields were planted, but due to wet soil conditions, pre-emergence herbicides were not applied,” the experts say. “We have received phone calls from corn growers about options for applying soil residual, pre-emergence herbicides after corn emergence.” If your applications have been delayed until after corn emergence, there are still several options available for you to use. There are several residual, pre-emergence herbicides such as Breakfree, Dual II Magnum, Harness, Keystone, Prowl h1O, Warrant, Zidua that can be applied after corn emergence without injury to corn, they say. But remember, these products won’t kill weeds present at the time of application. “These products do not have foliar activity and will not control weeds present at application,” say Jhala and Sandell. “Therefore, they should be tank-mixed with foliar herbicides labeled for corn. Some of the herbicides, including Anthem ATZ, Bicep II Magnum, Breakfree ATZ Lite, Confidence Xtra, Degree Xtra, FulTime NXT, Keystone LA NXT, Lumax EZ / Lexar EZ, Stalwart Xtra, and Volley ATZ NXT contain active ingredients (such as atrazine) that have foliar activity.”

When applied at the correct weed growth stage, they will provide burndown activity. Check the label for additional information, such as the need for tank-mix partners or spray additives to improve control of existing weeds. Also, application timing and other restrictions of tank-mix herbicide partners as noted in on the label. “Attempting to save a trip across the field by applying an herbicide with a liquid nitrogen fertilizer solution, such as 28% urea ammonium nitrate (UAN), as the carrier is not advisable if corn has emerged,” say Jhala and Sandell. “Tank-mix partners may cause other effects regardless of the application timing.”

For weeds such as glyphosate-resistant marestail, giant ragweed, common waterhemp, and kochia residual herbicides have been reported to be an effective tool for control, say Jhala and Sandell. However, the length and effectiveness of the residual active will vary based on: